Monday 25 August 2025

Researchers have long been fascinated by the idea of creating digital twins, virtual replicas of real-world objects that can be used for everything from simulation and testing to e-commerce and part inspection. But building these digital doubles has traditionally required specialized equipment like multi-camera arrays or laser scanners, which are often bulky and expensive.

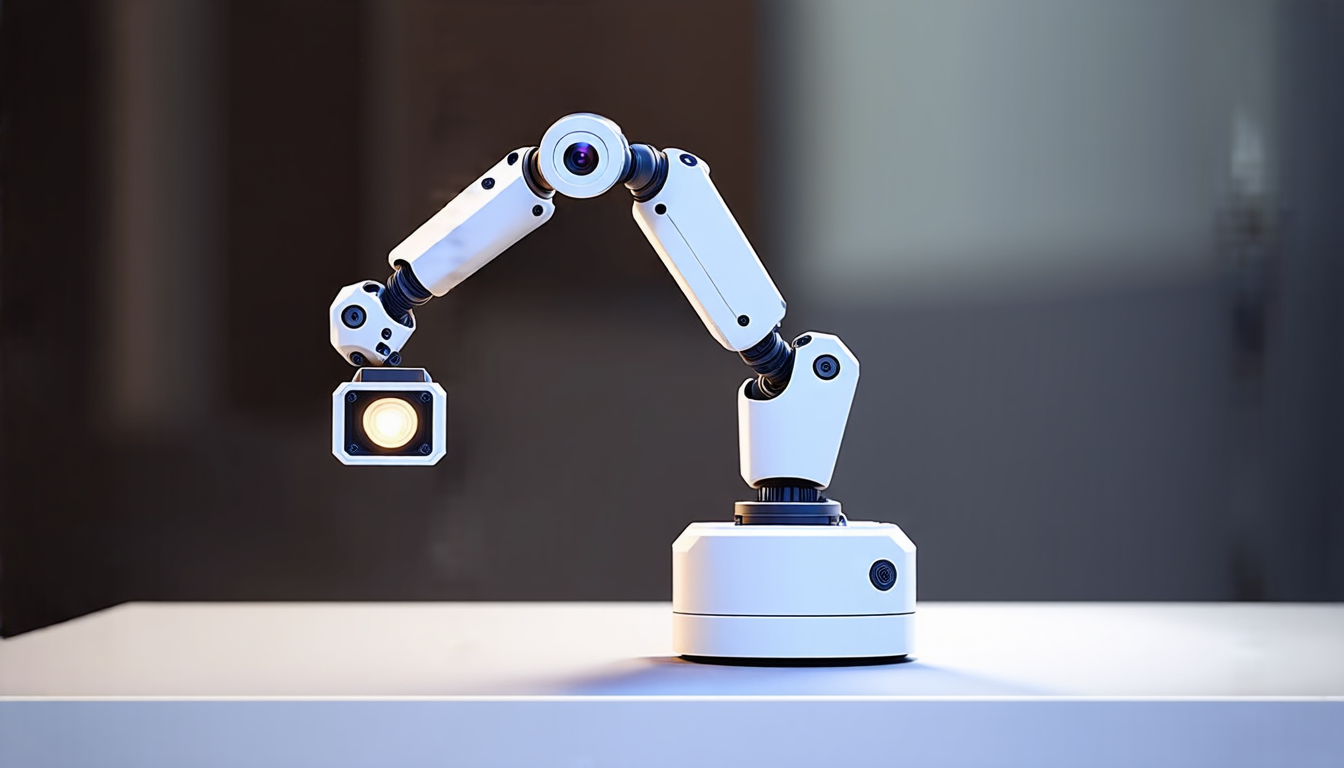

Now, a team of scientists at the University of California, Berkeley, has developed a new approach that uses a simple, affordable tool: a robot. Specifically, they’ve created an innovative robotic system called Omni-Scan, which can capture detailed 3D models of objects by rotating them in front of a single stationary camera.

The key to Omni-Scan’s success lies in its bi-manual design. The robot grasps an object with one gripper and rotates it while keeping the other gripper stationary against the background. This allows the system to isolate the object and remove any occluding surfaces, like the grip itself or the floor.

To create the 3D model, the researchers use a combination of techniques, including depth sensing, segmentation, and optical flow models. The result is a highly detailed digital twin that can be used for a wide range of applications, from part defect inspection to e-commerce product display.

The team tested Omni-Scan on 12 different industrial and household objects, achieving an average accuracy of 83.3% in identifying visual or geometric defects. While the system isn’t perfect – there’s still some room for improvement, particularly when it comes to handling transparent or reflective surfaces – its potential is undeniable.

One of the most exciting aspects of Omni-Scan is its potential to democratize digital twin creation. With a price tag that’s likely to be significantly lower than traditional scanning systems, this technology could make it possible for manufacturers, researchers, and hobbyists alike to create their own detailed 3D models without breaking the bank.

Of course, there are still many challenges to overcome before Omni-Scan can become a widely adopted tool. For one thing, the system will need to be adapted for use in different environments – such as outdoor settings or spaces with unusual lighting conditions. Additionally, the team will need to continue refining their algorithms and techniques to handle more complex objects and situations.

Despite these challenges, the potential benefits of Omni-Scan are undeniable. By making it possible to create detailed digital twins using a simple robot and a single camera, this technology could revolutionize everything from manufacturing and quality control to e-commerce and beyond.

Cite this article: “Robot-Captured Digital Twins Revolutionize Object Inspection and Creation”, The Science Archive, 2025.

Digital Twins, Robotics, 3D Models, Camera, Scanning, Manufacturing, Quality Control, E-Commerce, Part Inspection, Defects