Wednesday 10 September 2025

A team of researchers has made a significant breakthrough in developing an intelligent algorithm that can detect internal leaks in hydraulic systems, which are commonly used in industries such as manufacturing and construction.

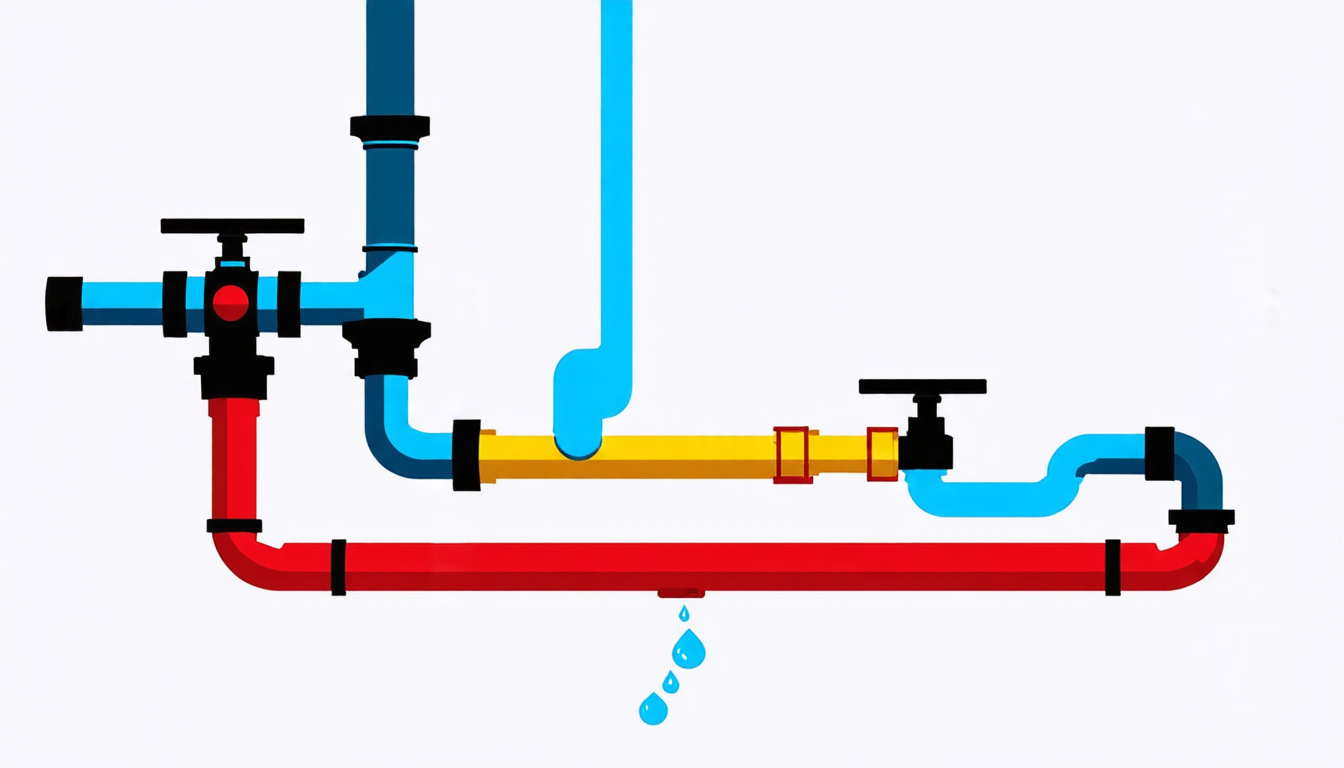

Hydraulic systems rely on the precise control of fluid pressure to operate machinery, vehicles, and other equipment. However, when internal leaks occur, it can lead to reduced performance, energy waste, and even catastrophic failures. Currently, detecting these leaks is a time-consuming and labor-intensive process that requires frequent inspections and maintenance.

The new algorithm uses advanced deep-learning techniques to analyze data from hydraulic systems in real-time, allowing for the detection of even small leaks before they become major problems. This is achieved by training artificial neural networks on large datasets of pressure signals and sensor readings from healthy and faulty systems.

The researchers used a laboratory hydraulic system to test their algorithm, collecting data under various leakage conditions. They found that their algorithm was able to accurately detect and classify leaks in real-time, with an accuracy rate of 95.81%.

The implications of this technology are significant. For industries that rely heavily on hydraulic systems, this algorithm could help reduce downtime and maintenance costs by detecting leaks early on. It could also improve the overall efficiency and reliability of these systems.

One of the biggest advantages of this technology is its ability to be implemented in real-time, allowing for immediate detection and response to leaks. This is particularly important in industries where even a few minutes of downtime can result in significant losses.

The algorithm has already been tested on a laboratory scale, but it’s expected that it will soon be implemented in industrial settings. The researchers are hopeful that their technology will have a major impact on the reliability and efficiency of hydraulic systems.

In addition to its practical applications, this research also highlights the potential of artificial intelligence to solve complex problems in various fields. By combining advanced algorithms with real-world data, AI has the ability to learn and adapt to new situations, making it an increasingly powerful tool for scientists and engineers.

As this technology continues to evolve, it’s likely that we’ll see even more innovative applications of AI in industries such as manufacturing, healthcare, and transportation.

Cite this article: “Intelligent Leak Detection Algorithm Revolutionizes Hydraulic System Maintenance”, The Science Archive, 2025.

Hydraulic Systems, Artificial Intelligence, Deep Learning, Leak Detection, Algorithm, Real-Time Monitoring, Manufacturing, Construction, Reliability, Efficiency.