Monday 07 April 2025

The quest for optimal packing has been a long-standing challenge in computer science and logistics. From fitting items into a moving truck to arranging components on a printed circuit board, efficient packing is crucial for minimizing waste and maximizing productivity. Now, researchers have developed a new algorithm that tackles this problem with unprecedented efficiency.

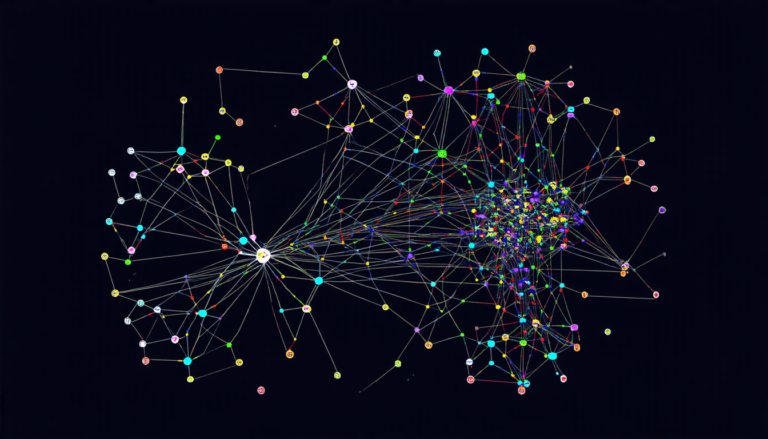

The team’s approach involves modeling the packing process as a linear arithmetic formula, which can be solved using specialized software. This allows them to identify the optimal arrangement of objects in just seconds, making it much faster than previous methods. The algorithm is particularly effective for complex shapes and irregularly sized items, where traditional packing techniques often fall short.

One key innovation behind this new approach is a technique called counterexample-guided abstraction refinement (CEGAR). Essentially, the algorithm starts with a simplified model of the packing problem and then gradually refines it based on any errors or inconsistencies that arise during the solution process. This iterative refinement enables the algorithm to quickly identify and eliminate suboptimal solutions.

To test their method, the researchers applied it to a range of real-world scenarios, including packing 3D printer parts and arranging components on printed circuit boards. In each case, their algorithm outperformed existing methods in terms of efficiency and accuracy.

The implications of this breakthrough are significant. For industries that rely heavily on efficient packaging, such as logistics and manufacturing, the new algorithm could lead to substantial cost savings and increased productivity. Additionally, the technique has potential applications in fields like medicine, where optimizing the arrangement of medical devices or pharmaceuticals can be a matter of life and death.

While this achievement is certainly impressive, it’s not without its limitations. The algorithm is currently limited to solving problems with a fixed number of objects, which may not be suitable for scenarios where the number of items is variable. However, the researchers are already working on extending their approach to accommodate these situations.

In short, this new packing algorithm represents a significant step forward in the quest for efficient packing and arrangement. By leveraging advanced mathematical techniques and iterative refinement, it’s capable of solving complex problems that have long stumped engineers and logisticians alike. As industries continue to grapple with the challenges of optimizing their packaging processes, this breakthrough is sure to play a key role in shaping the future of logistics and manufacturing.

Cite this article: “Sequential 3D Printing Made Efficient: A CEGAR-Driven Approach to Packing Complex Objects”, The Science Archive, 2025.

Packing, Algorithm, Optimization, Efficiency, Logistics, Computer Science, Linear Arithmetic Formula, Counterexample-Guided Abstraction Refinement, Cegar, Packing Problem, 3D Printer Parts